Our Products

Home > Our Products

Our Products

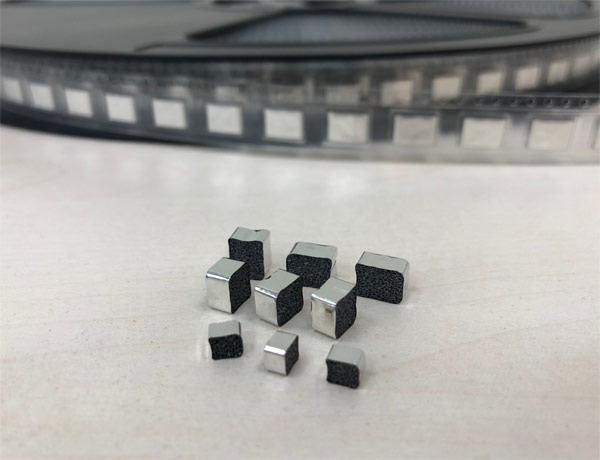

- Reduce by solder problem of poor contact

- Ensure that the substrate FG strengthen the reliability of the contact portion

- Prevent machine vibration to increase screws relaxation

- EIA standardized package, improve production efficiency

- Reduce by solder problem of poor contact

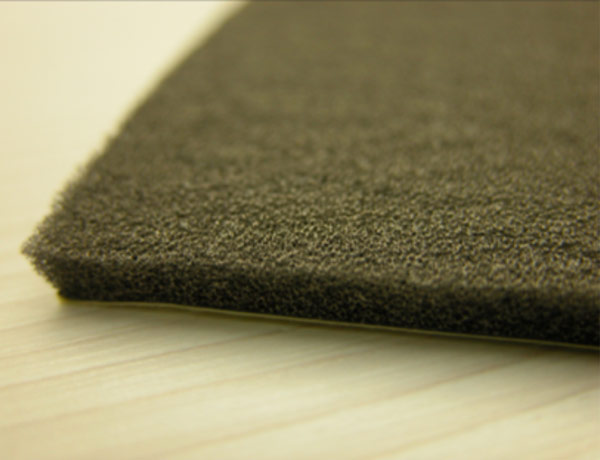

- Alloy Foil over Retardant Urethane Foam

- Low surface resistance and abrasion resistance

- Effective ESD solutions and excellent EMI shielding

- High compression resistance and is not deformed or broken advantages

- Alloy Foil over Retardant Urethane Foam

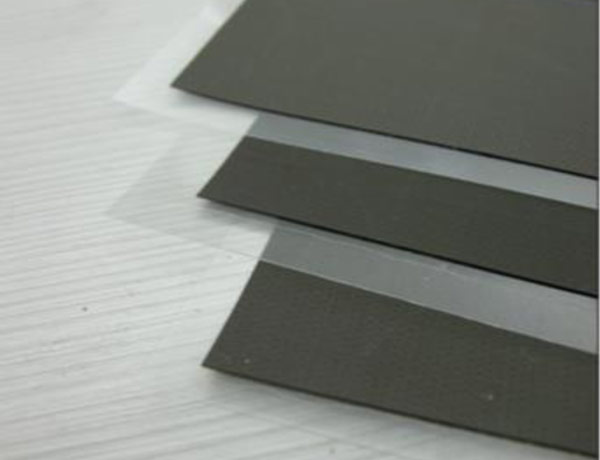

- Alloy Foil over Retardant silicone rubber

- Low surface resistance and abrasion resistance

- Effective ESD solutions and excellent EMI shielding

- High compression resistance and is not deformed or broken advantages

- Alloy Foil over Retardant silicone rubber

- Cheap and reduce the work circle time

- Normalized design, reduce product design time

- Superior mechanical properties, suitable for a variety of purposes

- EIA standardized package, improve production efficiency

- Cheap and reduce the work circle time

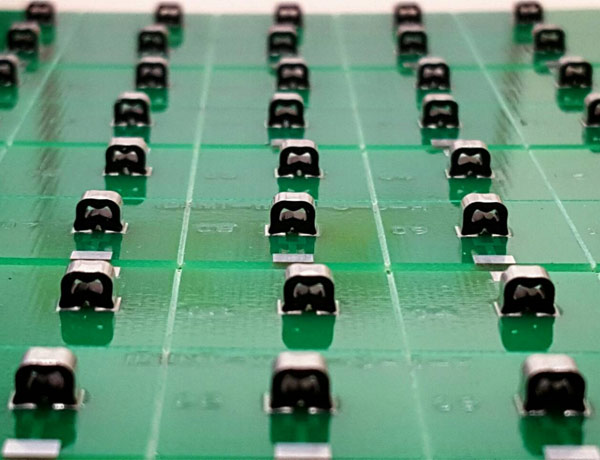

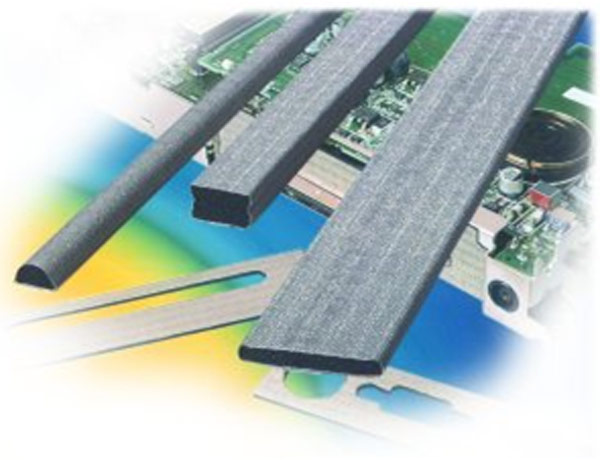

- Low DC resistance and high shielding effectiveness

- After accelerated life test has excellent reliability (ALT)

- Good high compression percentage and lower compressive force

- Reducing the fixed point, adding more space function

- Low DC resistance and high shielding effectiveness

- KPGB Series-Black Color (Surface Treatment: Anti Tarnish Urethane Coated= ATU). High compression conductive PU foam mixed with Tin.

- Low DC resistance and high shielding effectiveness

- After accelerated life test has excellent reliability (ALT)

- KPGB Series-Black Color (Surface Treatment: Anti Tarnish Urethane Coated= ATU). High compression conductive PU foam mixed with Tin.

- Low DC resistance and high shielding effectiveness

- After accelerated life test has excellent reliability (ALT)

- Good high compression percentage and lower compressive force

- PE material air cushion, good wear resistance

- Low DC resistance and high shielding effectiveness

- Most be reliable electrostatic solutions and excellent electromagnetic protection

- Superior conductivity and compression resilience force

- Can offer many kinds of size and shape and provide customized request

- Can provide various types of EMI Shielding I/O gasket

- Most be reliable electrostatic solutions and excellent electromagnetic protection

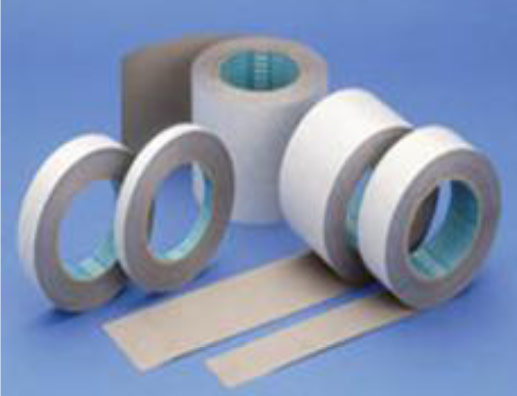

- Effective electrostatic solution and excellent EMI and RFI shielding

- Available in a variety of sizes and shapes, it can also be combined with different specifications of insulating film or adhesive and can be widely used in any electronic product

- Effective electrostatic solution and excellent EMI and RFI shielding

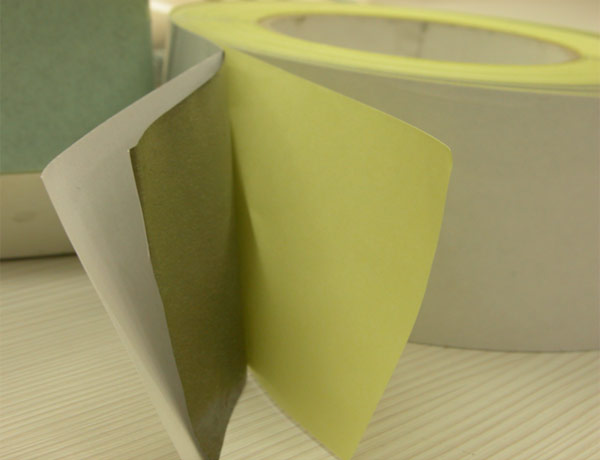

- Easy die cut and adhesive for other materials, increased functionality

- Not adhesive residue, easy processing

- Good contact with both hard and soft surfaces

- X-Y-Z axis conduction direction with excellent conductive properties

- Easy die cut and adhesive for other materials, increased functionality

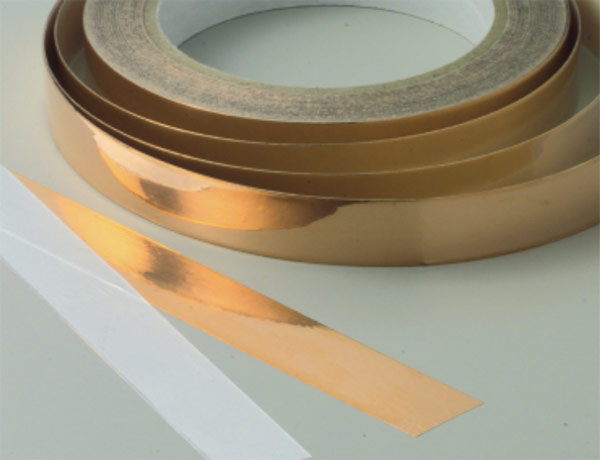

- Our Copper Foil Tapes can be able to use in RFI and EMI shielding applications of the electrical and electronic products.

- Our Copper Foil Tapes can be able to designed for use in applications where electrical or thermal conductivity is required and can be soldering

- Our Copper Foil Tapes can be able to use in RFI and EMI shielding applications of the electrical and electronic products.

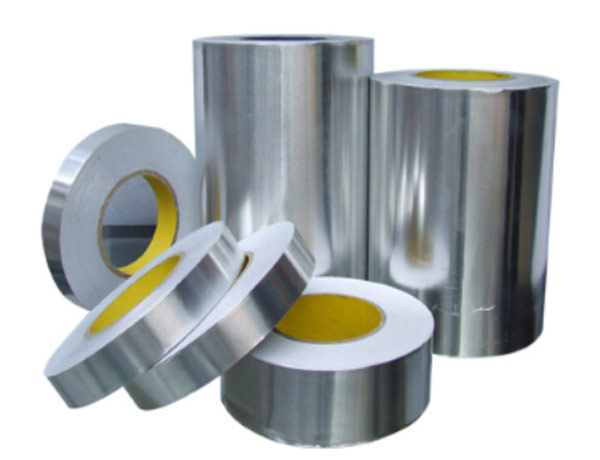

- Our Aluminum Foil Tapes can be able to use in RFI and EMI shielding applications of the electrical and electronic products.

- Our Aluminum Foil Tapes can be able to designed for use in applications where electrical or thermal conductivity is required and cheaper.

- Our Aluminum Foil Tapes can be able to use in RFI and EMI shielding applications of the electrical and electronic products.

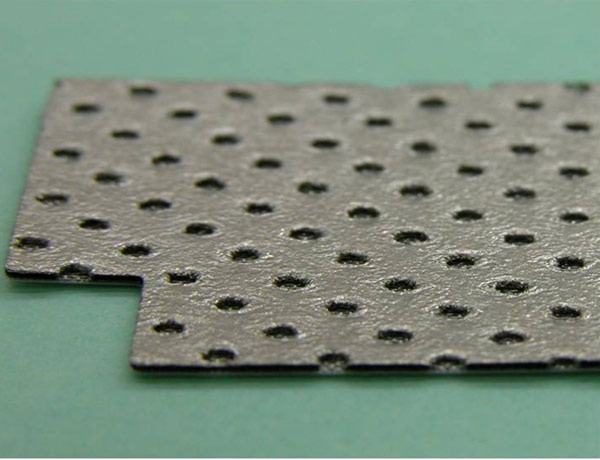

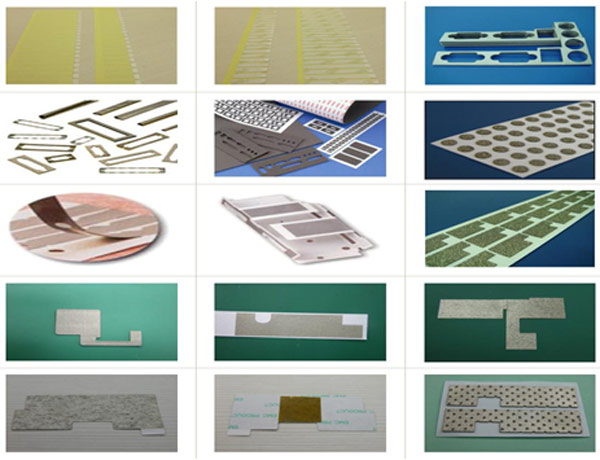

- Can be based on customer demand for design, punching or processed into desired size

- Can be used with any combination of material to meet the problem occurs between the conductive and insulating

- The mold speed is fast and simple knife, punching processing to send samples fast

- The die-cut of top technology, tolerance coefficient is extremely small, good quality

- Can be based on customer demand for design, punching or processed into desired size

- EMI absorber materials can be solutions that can be applied when there is no time to do major redesigning of the board layout.

- EMI absorber materials can be able to convert EMI noise into negligible heat energy.

- They work effectively at various frequency ranges from the KHz and MHz range up to the higher GHz range. With non-conductive adhesive on one side.

- They can be easily applied directly over ICs, CPUs, graphic chips, and even cables without fear of short-circuiting.

- EMI absorber materials can be solutions that can be applied when there is no time to do major redesigning of the board layout.

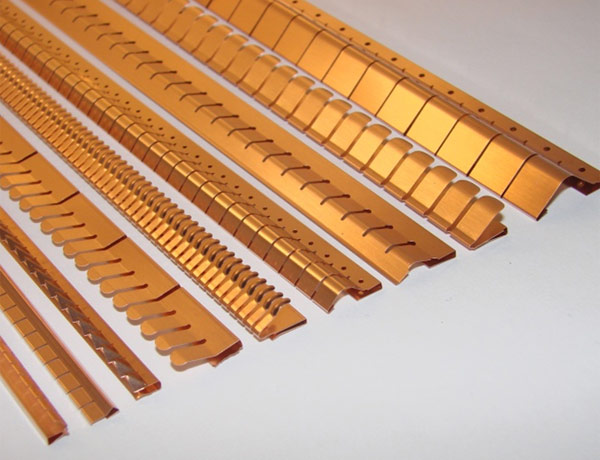

- Customer can choose different material (Be-Cu / Pb-Cu / Ti-Cu / SUS301/ SUS304....) and plating metal layer (Bright Nickel / Matte Nickel / Sn / Au....)

- Nearly 200 kinds of size and shape to choose from, saving the time and expense of the mold, and provide customized needs from all customer.

- Customer can choose different material (Be-Cu / Pb-Cu / Ti-Cu / SUS301/ SUS304....) and plating metal layer (Bright Nickel / Matte Nickel / Sn / Au....)

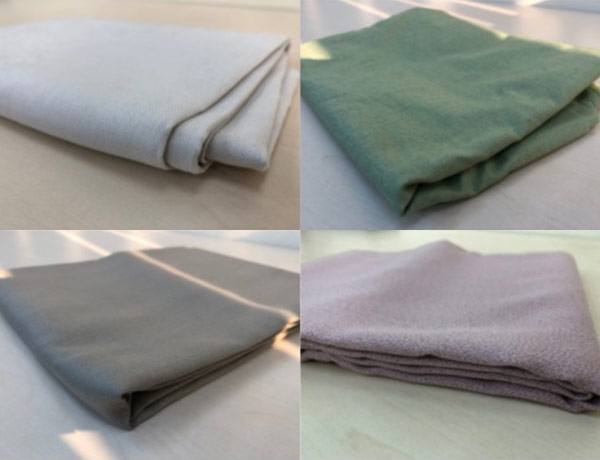

- Extensive selection of conductive and shielding fabrics.

- Variations of corrosion resistance, weight, color, bio-compatibility. Solid weaves, meshes, knit and non-woven available.

- Smart textiles need to be highly conductive and can transmit physiological signals to the sensing element, Conductivity comes from conductive textiles.

- Extensive selection of conductive and shielding fabrics.