This structure is conductive fabric fiber yarn fabric surface of each root metal structure. Each root using the metal thin film formed on the fibers, the fibers can be characterized in the use under, endowed with characteristics of the metal. If the film laminate, resin coating technique, is not the whole of the conductive fabric, but also damaged the softness deposition, sputtering and other gas-based treatment in only one treatment, although they could form a metal film , but it is difficult to conductivity of the fabric, and a low level of electrical conductivity. Complex shapes with tactile metal fiber fabric treatment to non-electrolytic plating solution-based processing approach is the best method. Electroless plating using the adhesiveness of the metal film on the fibers of the compound treatment, the metal foil can be obtained, and the same conductivity. Conductive fabric technology currently virtuous average resistance value 0.03Ω / sq.in (Contact Resistance). The use of metal complexes can be endowed with fibers having electromagnetic shielding performance. Fiber or plastic on the electromagnetic wave, the system is a transparent material, the electromagnetic radiation will penetrate the material, but the use of metal-based electromagnetic wave impedance of the interface inconsistencies with the mirror like reflection of light in nature. Such electromagnetic wave shielding property is represented by a metal conductive material have the features, mostly of a 40dB (shielding rate of 99%) ~ 100dB (shielding rate of 99.999%) performance.

Product Benefits

- Conductive cloth tape measures are the most basic products.

- There are different thickness and materials to choose from.

- According to different needs of customers, cutting and punching various sizes.

- According to the needs of customers, the combination of different materials and design of secondary processing

- Conductive adhesive according to customers need to select and non-conductive plastic.

- Can even choose non-conductive adhesive and conductive adhesive thickness and material

- Insert the different materials according to customer needs and the thickness of the insulating film.

- The best conductivity and the lowest resistanc

Product Features

Conductive fabric mainly characterized in that the fiber is soft and flexible, also did not found the others material better than the fiber material. In addition to it is the inimitable, such as lightweight, durable material characteristics.

In the same as the cross-sectional area of the cloth strip tensile strength, even with polyester lining and nylon wire all over than the steel, nylon, and carbon fiber has exceeded than steel 10 times the intensity. Its light weight and its weight ratio of the view can be said to have exceeded 100 times the intensity than steel. Structural diversification also overwhelms other material. Such as polyester, nylon and acrylic yarns composed of various, various cross-sectional shape of the yarn, fabric, circular knitting, and warp knitted fabrics, non-woven fabric of so many ways and structures and so on. This fiber industry has long been cultivated by technology in other material even in the other industry is an unimaginable world.

|

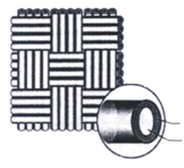

Conductive fiber yarns is that has a covered by the metal coating results,

both combined conductive excellent softness.

Density: 150-300 yarns / square inch

Surface impedance: <0.05Ohm/sq.in

Material: Plane Weave,Plaid Ripstop,

Normal Non-woven, Ultra thin non-woven

Plate: ( Ni / Cu / Ag / Au… )

Fabric : ( Polyester / Nylon… ) |

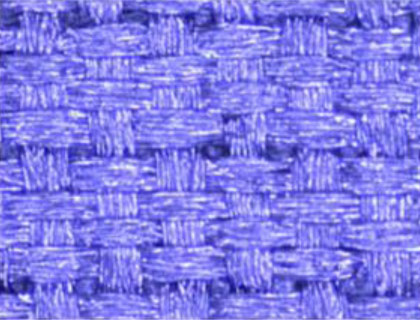

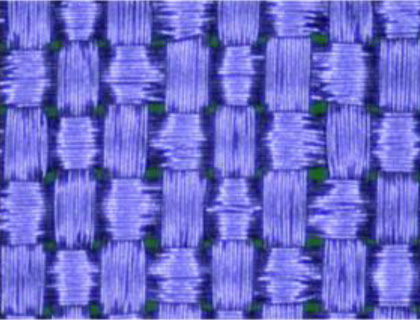

| Rip Stop Woven Fabric |

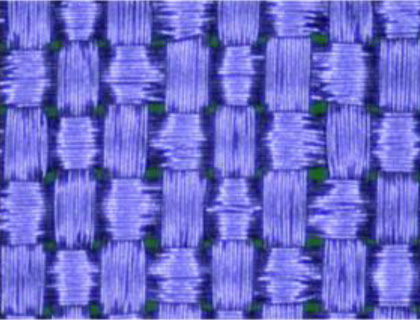

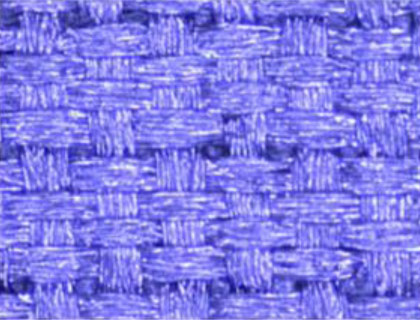

Plain Woven Fabric |

|

|

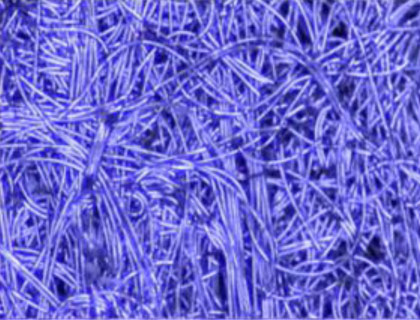

| Normal Non-Woven Fabric |

Ultra Thin Non-Woven Fabric |

|

|

| Currently conductive fabric can be divided into plain weave woven, Plaid RipStop woven, generally non-woven fabric and ultra thin non-woven fabric |

| Conductive fabric weave |

Figure marked |

Application Characteristics |

100% Polyester Fabric

Plain Woven Fabric |

|

- Soft and flexible, can be bent around and still have excellent continuity

- Elongation of good, easy to use in the tortuous and irregular bodies

- Superior adhesion and holding power, stable and reliable quality

- Thickness of thinnest: 0.02mm

|

100% Polyester Fabric

Ripstop Woven Fabric |

|

- Excellent abrasion resistance, suitable for use in extrusion resistance and tear resistance mechanical of products tensile and tear strength, can be effective against destructive testing

- superior adhesion and holding power, stable and reliable quality

- 4. Thickness of thinnest: 0.02mm

|

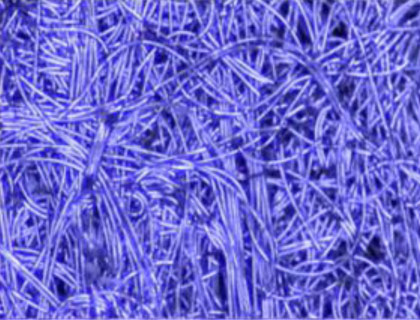

100% Polyester Fabric

Normal Non-Woven |

|

- Normal conductive non-woven; the thinnest is 0.15mm

- Non-woven materials mainly to complement the customer desired height, and has a compression ratio of 30%

- The current thickness: 0.15 / 0.25 / 0.37 / 0.5 / 0.6 / 0.8 / 1.0mm

- can be affixed to other fabrics, it is a good shielding effective or conductive in the low height of the space.

- 0.15t & 0.25t (Left fig.); the others thickness (Right fig.)

|

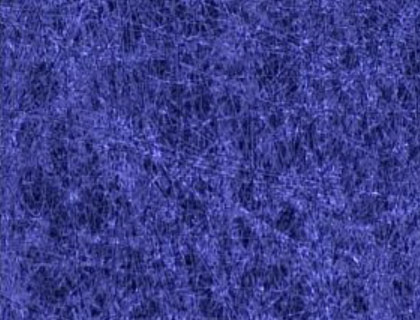

100% Polyester Fabric

Ultra Thin Non-Woven |

|

- An ultra-thin non-woven filament and staple fiber can be divided into long-fiber (Right Fig.), Material Adhesive thickness between 0.01to 0.05mm.

- Excellent conductivity Conductive cloth tape, with 30%compression capability and high-performance EMI shielding capability.

- Staple fiber (Left Fig.), Thickness of thinnest is 0.03mm; suitable use in conductive substrate double-sided adhesive tape

|

Conductive cloth tape is the most basic electromagnetic interference countermeasure products.

There are various options on the thickness and characteristics.

Conductive adhesive of the type or thickness can be selected according to customer needs.

You can even select a non-conductive adhesive, conductive adhesive thickness and material.

According to different needs of customers, cutting and punching various sizes

Based on customer needs, combined with different materials and designs secondary processing

According to customer needs and the thickness of the insulating material, fit in different conductive material

Product Structure

| Product Structure |

| Conductive Fabric (Layer-1) |

| Conductive Adhesive Tape (Layer-2) |

| Release Liner (Layer-3) |

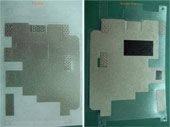

Product Code

| FCTP |

– |

60 x 30 |

x |

0.05t |

-1 |

| 〔1〕 |

|

〔2〕〔3〕 |

|

〔4〕 |

〔5〕 |

| 〔1〕 |

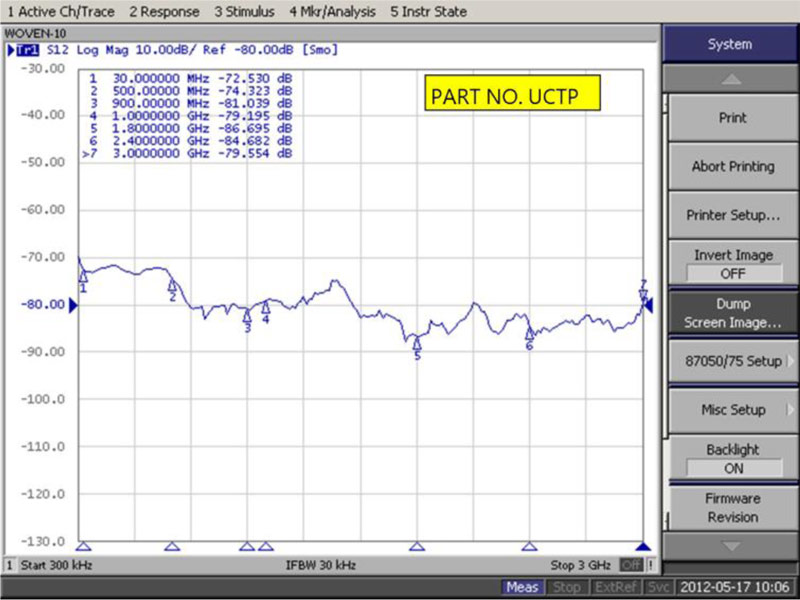

Product No.: FCTP/ UCTP / M323 / Q840……. |

| 〔2〕 |

Length(mm) |

| 〔3〕 |

Width (mm) |

| 〔4〕 |

Thickness(mm) |

| 〔5〕 |

Custom of die cutting |

|

|

|

|

|

|

Plain

Woven Fabric |

Ripstop Woven Fabric |

Black Color Fabric |

Normal Non-Woven |

Ultra Thin Non-Woven |

| 物性及料號一覽表 |

| Plain Woven and Plaid Ripstop Woven Fabric Type |

| Item |

Part No. |

Woven

Fabric

Type |

Total

Thickness

mm |

Conductive

Fabric

Color |

Surface Resistance

Ω/sq.in

Warp / Weft |

Contact

Resistance

Ω/sq.in |

Peel 180°

Adhesion

gf / SUS |

300kHz

-3GHz

dB (AVG.) |

Standard Size

W: mm x L:M

Per Roll |

| 1 |

FCTP020 |

Plain

Woven |

0.02 |

Gray |

0.057/ 0.048 |

0.025 |

650 |

63.14 |

1250mm x

50M |

| 2 |

FCTB020 |

Plain

Woven |

0.02 |

Black |

0.048/ 0.047 |

0.05 |

650 |

68.04 |

1250mm x

50M |

| 3 |

FCTP030 |

Plain

Woven |

0.03 |

Gray |

0.034 / 0.026 |

0.025 |

800 |

75.00 |

1250mm x

50M |

| 4 |

FCTN030 |

Ripstop

Woven |

0.03 |

Gray |

0.040 / 0.026 |

0.025 |

800 |

73.05 |

1250mm x

50M |

| 5 |

FCTB030 |

Plain

Woven |

0.03 |

Black |

0.035 / 0.028 |

0.05 |

800 |

76.51 |

1250mm x

50M |

| 6 |

FCTP050 |

Plain

Woven |

0.05 |

Gray |

0.033 / 0.028 |

0.025 |

1050 |

67.46 |

12250mm x

50M |

| 7 |

FCTN050 |

Ripstop

Woven |

0.05 |

Gray |

0.040 / 0.026 |

0.025 |

1050 |

66.32 |

1250mm x

50M |

| 8 |

FCTB050 |

Plane

Weave |

0.05 |

Gray |

0.033 / 0.028 |

0.05 |

1050 |

67.46 |

1250mm x

50M |

| 9 |

Q840070 |

Plain

Woven |

0.07 |

Gray |

0.033 / 0.022 |

0.025 |

1250 |

72.97 |

1250mm x

50M |

| 10 |

FCTB070 |

Plain

Woven |

0.07 |

Black |

0.05 / 0.05 |

0.05 |

1150 |

65 |

1250mm x

50M |

| 11 |

FCTB090 |

Plain

Woven |

0.09 |

Black |

0.05 / 0.05 |

0.05 |

1250 |

65 |

1250mm x

50M |

| 12 |

M834H |

Plain

Woven |

0.10 |

Gray |

0.05 / 0.05 |

0.05 |

1350 |

65 |

1250mm x

50M |

| 13 |

Q840 |

Plain

Woven |

0.10 |

Gray |

0.033 / 0.022 |

0.012 |

1650 |

76.04 |

1250mm x

50M |

| 14 |

UCTB |

Plane

Weave |

0.12 |

Black |

0.038 / 0.025 |

0.025 |

1600 |

79.72 |

1000mm x

50M |

| 15 |

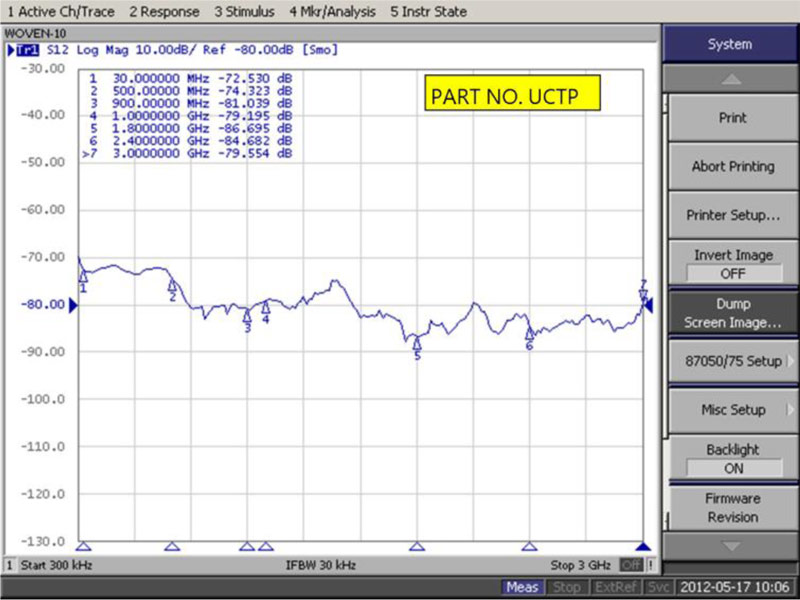

UCTP |

Plaid

RipStop |

0.12 |

Gray |

0.035 / 0.024 |

0.015 |

1600 |

79.60 |

1250mm x

50M |

| 16 |

M323 |

Plane

Weave |

0.12 |

Gray |

0.032 / 0.023 |

0.015 |

1680 |

72.88 |

1250mm x

50M |

| The above data is actual test value, not absolute value. |

| Normal Non-Woven and Ultra Thin Non-Woven Fabric Type |

| Item |

Part No. |

Non-Woven

Fabric

Type |

Total

Thickness

mm |

Conductive

Fabric

Color |

Bridge Resistance

Ω/10x30mm

Warp / Weft |

Volume

Resistance

Ω/10x10mm |

Peel 180°

Adhesion

gf / SUS |

300kHz

-3GHz

dB (AVG.) |

Standard Size

W: mm x L:M

Per Roll |

| 1 |

NW030 |

Ultra-Thin |

0.03 |

Light Gray |

0.045 / 0.022 |

0.015 |

600 |

74.27 |

610 x 50M |

| 2 |

NW040B |

Ultra-Thin |

0.05 |

Black |

0.05 / 0.05 |

0.05 |

600 |

65.00 |

610 x 50M |

| 3 |

NW045 |

Ultra-Thin |

0.05 |

Light Gray |

0.048 / 0.020 |

0.015 |

800 |

79.50 |

610 x 50M |

| 4 |

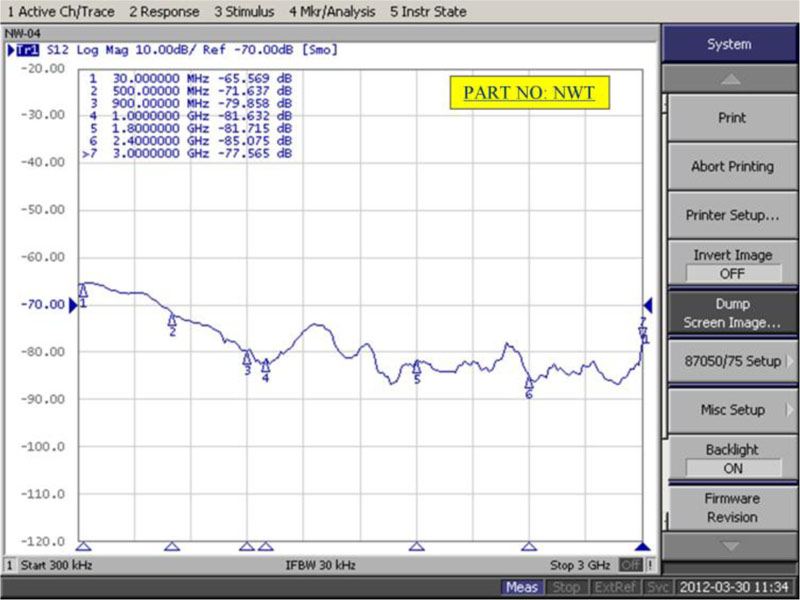

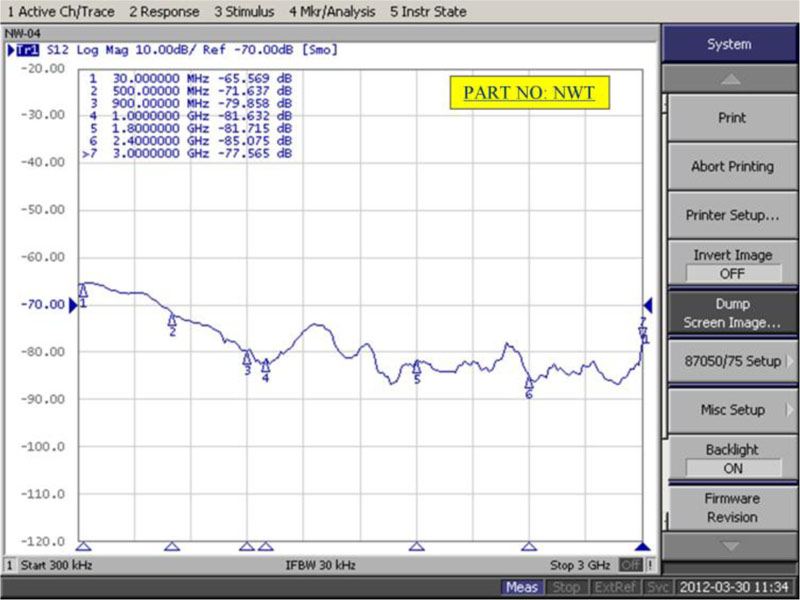

NWT |

Ultra-Thin |

0.07 |

Light Gray |

0.025 / 0.017 |

0.005 |

1680 |

77.58 |

1000 x 50M |

| 5 |

NW150 |

Normal |

0.15 |

Dark Gray |

0.034 / 0.020 |

0.01 |

1500 |

78.87 |

1100 x 50M |

| 6 |

NW250 |

Normal |

0.25 |

Dark Gray |

0.044 / 0.016 |

0.01 |

1500 |

80.73 |

1250 x 50M |

| 7 |

NW370 |

Normal |

0.37 |

Dark Gray |

0.015 / 0.021 |

0.01 |

1600 |

82.60 |

1250 x 50M |

| 8 |

NW600 |

Normal |

0.60 |

Dark Gray |

0.012 / 0.015 |

0.01 |

1600 |

84.68 |

1250 x 50M |

| 9 |

NW800 |

Normal |

0.80 |

Dark Gray |

0.010 / 0.009 |

0.02 |

1600 |

87.47 |

1250 x 50M |

*The above data is actual test value, not absolute value.

*Test Method

Thickness: Vernier caliper

Color: Visual / Color Card

Surface & Volume Resistance: ASTM D257 / JIS K7194

Peel 180° Adhesion : PSTC#1 / ASTM D3330

Shielding Effective (dB): ASTM D4935-89 (See below for example Figure) |

Conductive cloth tape is the most basic electromagnetic interference countermeasure products.

Conductive cloth tape is the most basic electromagnetic interference countermeasure products. Conductive adhesive of the type or thickness can be selected according to customer needs.

Conductive adhesive of the type or thickness can be selected according to customer needs. According to different needs of customers, cutting and punching various sizes

According to different needs of customers, cutting and punching various sizes