Our Products

Home > Our Products

Conductive PU Foam Gasket_KPGB Series

KPGB Series-Black Color (Surface Treatment: Anti Tarnish Urethane Coated= ATU).

- Product Benefits

- Product Benefits

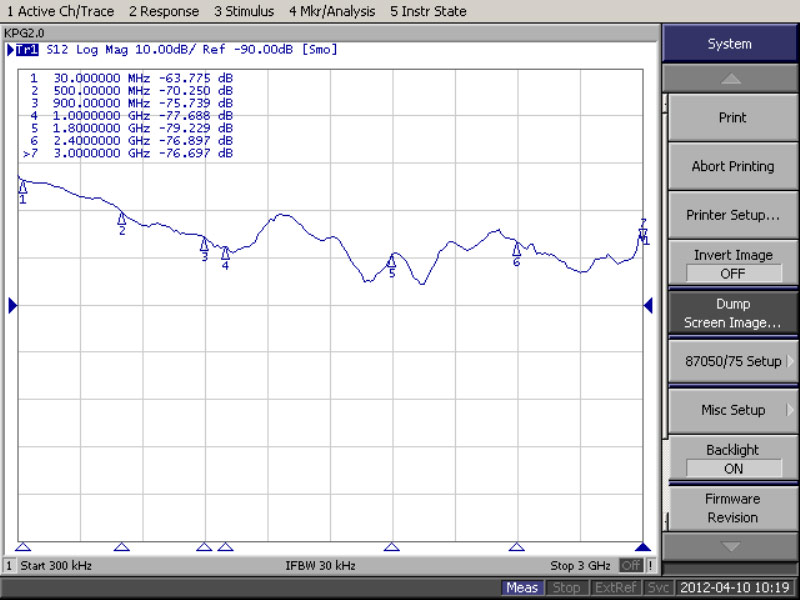

- Ultra-superior attenuation effectiveness

- High electrical conductivity

- Excellent resistance to compression characteristics

- Excellent corrosion resistance

- High performance cycle life

- Characteristics of high temperature applications

- Resistant to ultraviolet light and high humidity

- Low current conduction

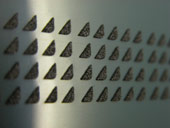

- Cost-effective of die cut

Product Features- Ultra-low DC resistance and high protective effect of electromagnetic waves

- Excellent reliability through experiments, accelerated aging life test (ALT)

- High stability and consistency of the small compressive force generated by the high compression ratio

- Increasing function of the space, reduce the fixed point.

- During in the production and assembly, Reducing the compression and extrusion force.

KPGB Series-Black Color Surface Treatment:

KPGB Series-Black Color Surface Treatment:

Anti-Tarnish Urethane Coated= ATU

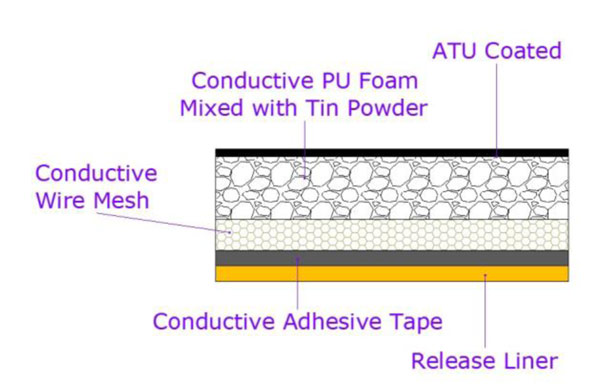

High compression conductive PU foam mixed with Tin.

KPG Series-high compression fully conductive PU foam semi-finished appearance, good for reel specifications, reduces cutting costs and high produce efficiency.

KPG Series-high compression fully conductive PU foam semi-finished appearance, good for reel specifications, reduces cutting costs and high produce efficiency.

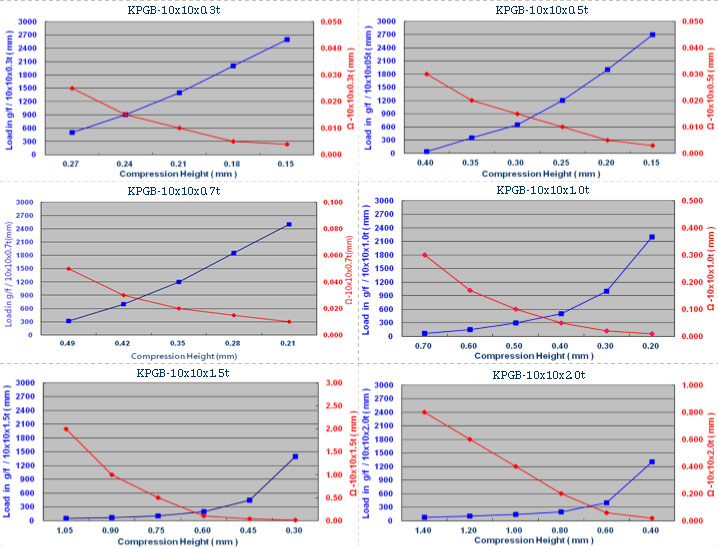

Each of thickness, there are different high compression conductive properties has more wide applications.

Each of thickness, there are different high compression conductive properties has more wide applications. In particular, applications in a very small space and on irregular material to better show its high compression conductivity. Cutting for clients can design and mass production of various shapes and sizes.

In particular, applications in a very small space and on irregular material to better show its high compression conductivity. Cutting for clients can design and mass production of various shapes and sizes.

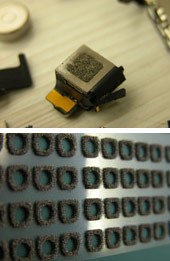

KPGB SERIES-Because of the high conductivity of PU foam mixed with tin powder, it enhances the electrical conductivity and heat resistance. It can be applied to high-temperature components in addition to small cabinets. Especially in irregular applications. The conductive object still has excellent electrical and EMI shielding effectiveness.

KPGB SERIES-Because of the high conductivity of PU foam mixed with tin powder, it enhances the electrical conductivity and heat resistance. It can be applied to high-temperature components in addition to small cabinets. Especially in irregular applications. The conductive object still has excellent electrical and EMI shielding effectiveness.

Product Structure Product Code

Product CodeKPGB – 30 x 10 x 0.3t - 1 〔1〕 〔2〕 〔3〕 〔4〕 〔5〕 〔1〕 KPGB Series 〔2〕 Length 〔3〕 Width 〔4〕 Thickness 〔5〕 Custom die cutting Product PropertiesPhysical Property / Part Series KPGB-0.3 KPGB-0.5 KPGB-0.7 KPGB-1.0 KPGB-1.5 KPGB-0.3 Material Conductive PU Foam mixed with Tin, Conductive Wire Mesh + ATU Adhesive Type Conductive Acrylic adhesive tape Color Black Recommended Compression Rate 30-70% Surface Resistance 0.20Ω / sq.in Contact Resistance 0.05Ω / sq.in Adhesion ≥ 1.0kgf Pore count 80 ppi Shielding Effective 65dB (AVG.) Service Temperature -10℃ ~ 85℃ Environmental Testing RoHS Compliant Standard Size Width: 950mm; Length: 30 meters *The above data is actual test value, not absolute value.

*Test Method: Thickness: Vernier caliper Color: Visual / Color Card Contact Resistance: ASTM D257

Peel 180° Adhesion: PSTC#1 / ASTM D3330 Shielding Effective (dB): ASTM D4935-89 (From 30MHz~3GHz) Shielding Effective (dB)

Shielding Effective (dB)

- Ultra-superior attenuation effectiveness