Our Products

Home > Our Products

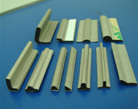

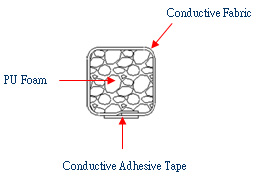

Fabric Over Foam Gasket

Conductive Fabric over Foam Gasket (EMI Shielding Gasket), there are more than 20 kinds of specifications, but also has different size for customers to choose. The product is a cheap and effective anti-electromagnetic shielding gasket.

- Product Benefits

- Product Benefits

- Ultra superior attenuation effectiveness

- High electrical conductivity

- Excellent resistance to compression characteristics

- Excellent corrosion resistance

- High performance cycle life

- Characteristics of high temperature applications

- Resistant to ultraviolet light and high humidity

- Low current conduction, ESD design,

- Cost-effective

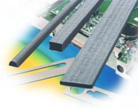

Product Features- Cover material: conductive fabric, copper foil, aluminum foil, tin foil, etc.

- Gasket Specifications: PU, CR, EPDM, PORON, Silicone Rubber

- Adhesive tape Specifications: conductive adhesive, insulation adhesive

- Surface impedance: <0.05Ω / sq.in (ASTM-D257)

- Contact resistance: <0.05Ω / sq.in (ASTM-D257)

- Working temperature: -30 to 70℃

- Friction test: 1,000 times = no change (ASTM-D3884)

- Compression Test: 22 hrs; 70℃; 50% compression = 95% response rate (ASTM-D395)

- Shielding efficiency: >65dB (AVG.) From 30MHz to 3GHz (ASTM-D4935-89)

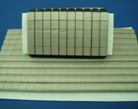

U-TEK Company conductive foam series, there are more than 20 kinds of the above specifications, but also has different size for customers to choose.

U-TEK Company conductive foam series, there are more than 20 kinds of the above specifications, but also has different size for customers to choose. Can die cut any specified for customer need, production and delivery very fast.

Can die cut any specified for customer need, production and delivery very fast.

Can customized over hundreds of I / O Gasket sizes; produce fast, low cost tooling.

Can customized over hundreds of I / O Gasket sizes; produce fast, low cost tooling. In response to customer demand, the outer layer of conductive fabric coating material in addition, there are also other materials such as: aluminum foil, aluminum foil and copper foil. As addition to PU foam, but also available Silicone rubber, CR Foam, EPDM, PORON etc...

In response to customer demand, the outer layer of conductive fabric coating material in addition, there are also other materials such as: aluminum foil, aluminum foil and copper foil. As addition to PU foam, but also available Silicone rubber, CR Foam, EPDM, PORON etc...

Adhesive tape combine with different specifications and materials, can be stuck on the conductive body, with a foam compression characteristics, with a wider range of applications, such as in a smaller space between the cavity and the cavity for the bonding.

Adhesive tape combine with different specifications and materials, can be stuck on the conductive body, with a foam compression characteristics, with a wider range of applications, such as in a smaller space between the cavity and the cavity for the bonding.

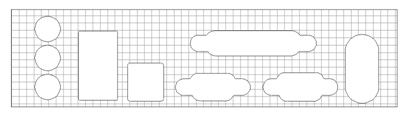

Product Structure Product Code

Product CodeUGTP – 10 x 6 x 30 mm CT -1 〔1〕 〔2〕 〔3〕 〔4〕 〔5〕 〔6〕 〔7〕 〔1〕 Part Series = UGTP ; UGTR ; UGTD ; UGTA ; UGTL ; UGTN ; UGPP ; UGTT 〔2〕 Width

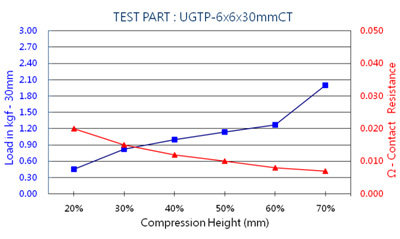

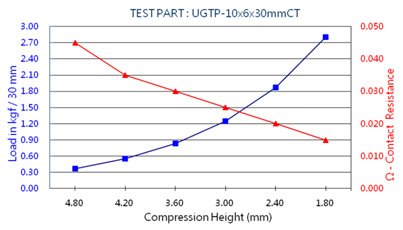

〔3〕 Height 〔4〕 Length 〔5〕 Unit : mm 〔6〕 CT= Conductive Adhesive Tape ; WT= Insulator Adhesive Tape ; NT = Non Adhesive Tape 〔7〕 -1= Die cut any shape ( Also can mention any description ) UGTP Type Contact Resistance and Compression-Load Deflection Square

UGTP Type Contact Resistance and Compression-Load Deflection Rectangle

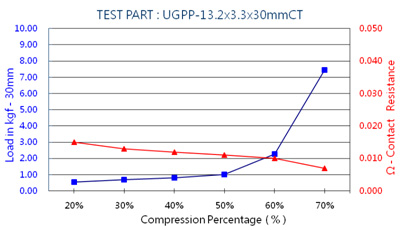

UGPP Type Contact Resistance and Compression-Load Deflection

UGTA Type Contact Resistance and Compression-Load Deflection

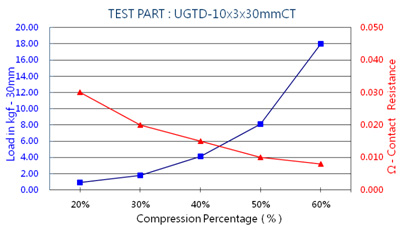

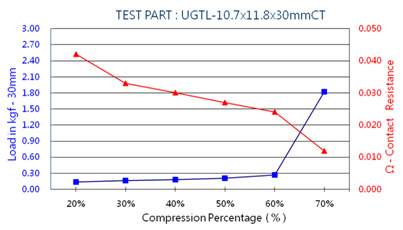

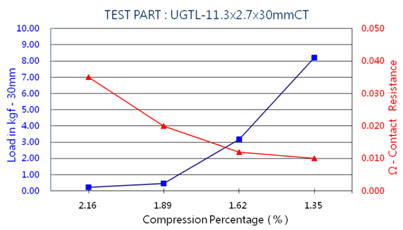

UGTL Type Contact Resistance and Compression-Load Deflection

UGTN Type Contact Resistance and Compression-Load Deflection

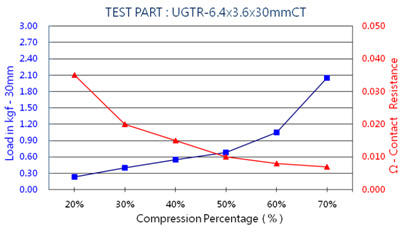

UGTR Type Contact Resistance and Compression-Load Deflection

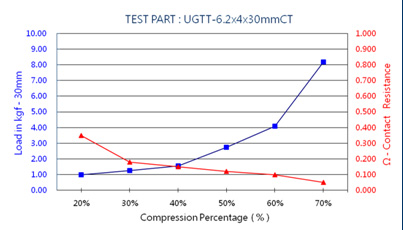

UGTT Type Contact Resistance and Compression-Load Deflection

GTO Type I/O Gasket ( Example )  The above values are actual test data, not absolute value.

The above values are actual test data, not absolute value.

There are more samples, please feel free to contact with us

- Ultra superior attenuation effectiveness