Product Name : Conductive Substrate Double Side Adhesive Tapes

Product Description

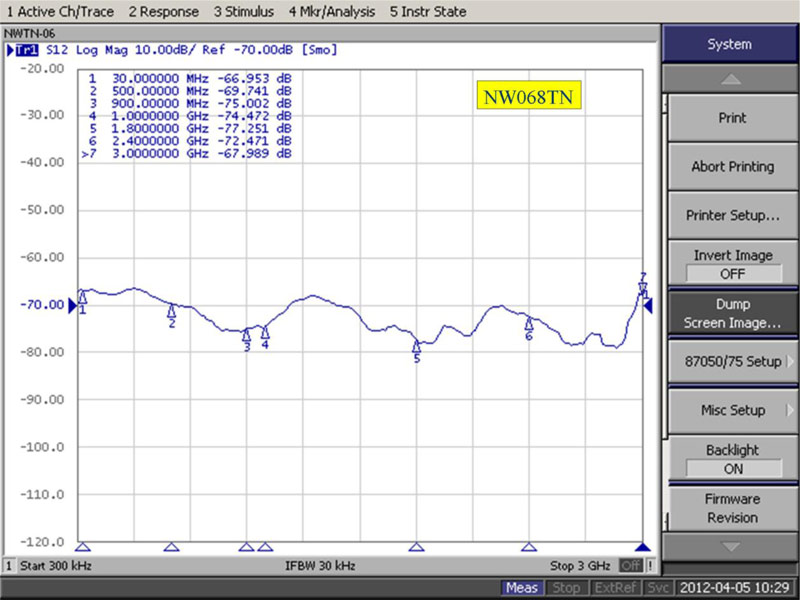

- NWTN Series - The kind of conductive substrate double-sided adhesive tape.

- NWTN Series - Can be vertical conduction (Z-axis) and horizontal transverse conduction (X-Y axes) function.

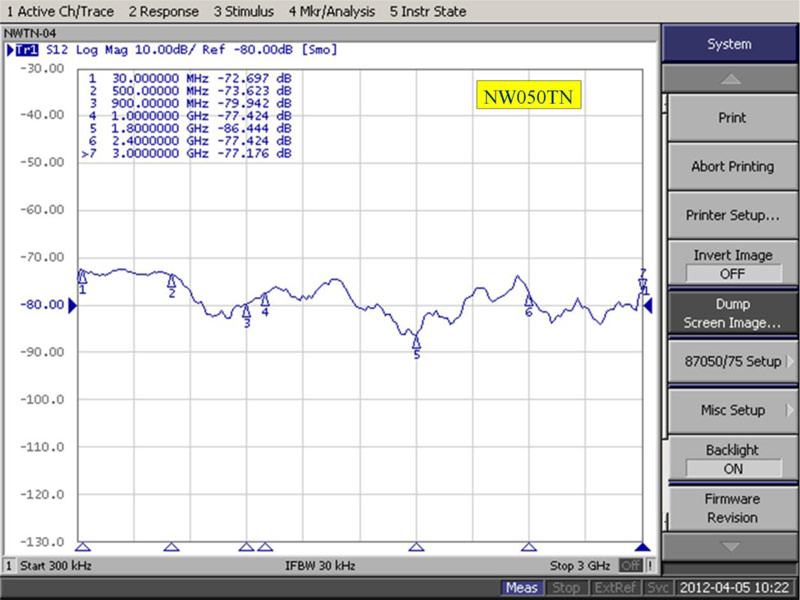

- NWTN Series - Good for EMI / RFI Shielding, or use conductive grounding gasket adhesion to metal surfaces is very suitable.

- NWTN Series - conductive substrate double-sided adhesive tape using a conductive non-woven fiber material with a conductive acrylic double-sided pressure sensitive adhesive, to form a high viscosity and high conductivity, and more excellent physical properties of the conductive duplex tape.

- NWTN Series - The kind of conductive substrate double-sided adhesive tape.

- NWTN Series - Can be vertical conduction (Z-axis) and horizontal transverse conduction (X-Y axes) function.

- NWTN Series - Good for EMI / RFI Shielding, or use conductive grounding gasket adhesion to metal surfaces is very suitable.

- NWTN Series - conductive substrate double-sided adhesive tape using a conductive non-woven fiber material with a conductive acrylic double-sided pressure sensitive adhesive, to form a high viscosity and high conductivity, and more excellent physical properties of the conductive duplex tape.